Harmonics, Stray Voltage, Location: CSV vs VFD

We have discussed the differences in how a Variable Frequency drive or VFD, and a Cycle Stop Valve or CSV system, control a pump system. We also discussed energy savings and the differences in creating or de-rating the motor load. In this article we will discuss the electrical and environmental differences between VFD and CSV controls.

Sinusoidal or Square Wave?

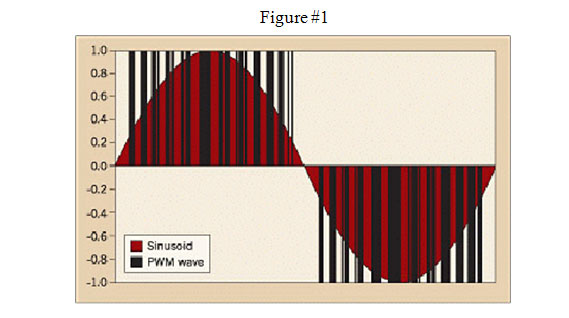

As seen in black on figure #1, A VFD can pulse at 6, 12, 18, or even higher pulses per cycle to try and simulate AC power. It is impossible to cap off these pulses at the fundamental voltage, so voltage spikes 4 to 5 times the fundamental voltage are commonly seen by the motor. For this reason most motor manufacturers have changed from the standard 600 volt insulation, to 2,000 volt insulation on motor windings, to be able to better survive these high peak voltages.

Pulsed DC power from a VFD can accumulate and voltage spikes increase even higher as the length of wire to the motor increases. For this reason filters or reactors are used to limit the voltage spikes to the motor. Filters and reactors help, but still allow considerable voltage spikes to the motor. Filters and reactors also have heat loss, which further reduces the efficiency of the system. The rapid rate of voltage rise and the increased number of pulses, is also very hard on motor insulation. The rapid rate of switching also creates harmonic content that piles on top of the fundamental voltage. The harmonic current powering the motor creates additional heat. These are the reasons why additional cooling is needed for VFD controlled motors.

A CSV has no electronics of it's own, and does not affect the power to the motor in anyway. As was discussed in Part 1, when controlled by a CSV, the motor always runs at full RPM, but the amperage will naturally vary with the volume of water produced.

The voltage and current wave-form of 60 hertz standard power has a smooth sinusoidal shape, as seen in red in figure #1. With sinusoidal power, peak voltage is controlled, and there is considerable time between low and high peaks. This is very easy on motors, and makes the squirrel cage induction motor a very reliable piece of equipment. Standard AC power does not have the accumulative effect of pulsed DC power. Filters and reactors are not needed, and increased wire length has no detrimental effect. With a CSV system, the motor is running on standard sinusoidal power and does not see the voltage spikes, rapid rate of voltage rise, or the harmonics that are a given with VFD systems.

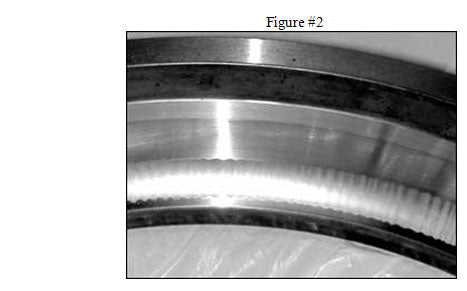

A VFD can pulse DC power to simulate 60 hertz when the motor needs to run at full RPM. As flow is reduced and the motor needs to slow down, the VFD pulses DC power to simulate frequencies below 60 hertz. 30 hertz is half speed for the motor, and is also the minimum speed that a submersible motor can operate to maintain the hydroplane effect on a Kingsbury type thrust bearing. Anything lower than 30 hertz or half speed, and the thrust bearing will quickly be destroyed. When soft starting with a VFD, the motor needs to be ramped up to 30 hertz in one second, to prevent bearing damage. Motors with ball bearings suffer the effects of EDM currents produced from the fast switching of VFD controls. These EDM currents cause electrical fluting, which can quickly destroy the races in ball bearings. See Figure #2.

Fluted Bearing

With CSV controls, thrust and axial bearings carry a little extra load as the back pressure increases, but do not experience the destructive electrical fluting problems created by VFD controls.

Environmental Differences

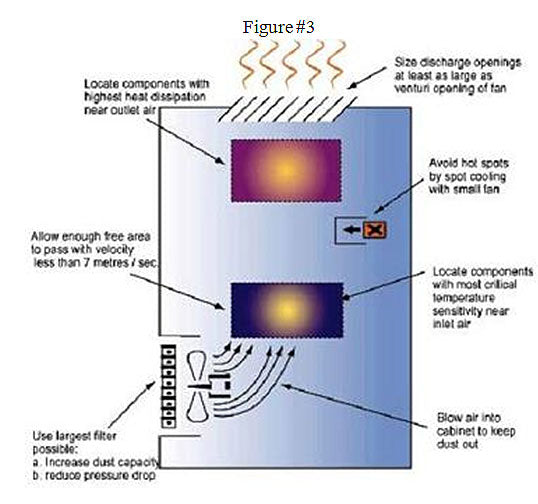

The electronics in a VFD are very similar to any computer. These electronics produce heat and must be kept cool. The most common means of cooling is by using a simple fan. See Figure #3. The ambient temperature inside a well house or other enclosure must remain below the recommended operating range of the VFD. If the VFD is installed outside or in an enclosure that is not temperature controlled, the ambient temperature can be warmer than the recommended operating temperature of the VFD. In this case the fan in a VFD is just blowing hot air, and will not be able to keep the VFD cool. In these cases a VFD must be installed inside a room with air conditioning. The need to air condition the room where the VFD is installed, adds to the total energy used by the system. I have seen mechanical rooms where the air conditioner, uses more energy than the VFD controlled pumps for which the room was built.

The fan in an air cooled VFD also draws in lint, dust, bugs, moisture, and anything else in the air. These contaminants can clog up the fan, or coat the electronics, and prevents the VFD from getting the cooling it needs. The fan itself also gives another opportunity for a malfunction.

VFD Cooling Fan

Harmonics?

VFD's also create harmonics that are sent back into the electrical grid. It is important to ground the VFD and motor properly. It is also important to isolate the VFD from other electrical devices like cordless phones, radios, and other communication signals. The control wires for the VFD must be installed in different conduits and kept a safe distance away from the power wires. Power and signal wires from VFD's should not be close to, or run parallel to, other wires and conduits, and should only cross other wires at a right angle.

A CSV on the other hand, has no electronics that need cooling. A CSV also does not create any electrical ?noise?, or other problems associated with VFD controls. High ambient temperatures do not affect a CSV in anyway. With a CSV, freezing is one of the only environmental concerns.

Understanding the truth will keep you from having to suffer the consequences.